KARTING

DYNOMOMETERS

Printer-friendly format

PART 2 - Fluid Brake Dynos

By

John Copeland

Last month we started

talking about different types of dynos and some of the basics about what

a dyno is and what it isn't. We talked about how important accurate data

was if you hoped to get anything meaningful from your dyno experience.

Over the years there have been dozens of outfits on the market that

claimed to top quality information for a bargain price. Don't believe

it! Last month we started

talking about different types of dynos and some of the basics about what

a dyno is and what it isn't. We talked about how important accurate data

was if you hoped to get anything meaningful from your dyno experience.

Over the years there have been dozens of outfits on the market that

claimed to top quality information for a bargain price. Don't believe

it!

While

the basic design of a dyno is pretty simple, a really good dyno is a

very sophisticated piece of equipment. If someone tells you they can

sell you a perfectly good, top quality dyno for a few hundred dollars,

well let me tell you, it just ain't so. Like in so many other things,

you get exactly what you pay for. A bargain-priced dyno may work ok to

break in engines on, but don't expect to get any consistent, worthwhile

data from it. A good, useful dyno is the result of untold hours of

sophisticated engineering. It must be robust enough to withstand the

rigors of repeated high-frequency vibrations. It must deliver

consistent, repeatable data. And it must be "user friendly." A

dyno that is a pain to use....simply won't get used for long. Let's

begin by looking at the basic fluid brake dyno.

If

you remember from last month, a dyno measures engine output by comparing

it to a known, or measurable resistance, called the load. In the vast

majority of dynos in use today, either oil or

water circulating through a pump provides that load. The concept is simple: the harder you

make the pump work, the harder it makes the engine work. If you increase

the load on the pump to the point that the engine can't generate enough

power to drive the pump, the engine will slow down. Since that slows

down the pump, it reduces the load on the pump and the system stabilizes

at the new, lower RPM. Likewise, if you reduce the load on the pump, the

RPM of the engine will increase until it reaches equilibrium between the

power output of the engine and the load on the pump. In most cases the

load on the pump is controlled by means of a valve on the output side of

the pump. Take a look at the diagram in Figure 1 and you'll get the

idea. By putting a valve in the line running out of the pump, you can

control how hard the pump has to work. As you close down the valve, the

pump tries harder to push the water or oil through the smaller opening. If

you remember from last month, a dyno measures engine output by comparing

it to a known, or measurable resistance, called the load. In the vast

majority of dynos in use today, either oil or

water circulating through a pump provides that load. The concept is simple: the harder you

make the pump work, the harder it makes the engine work. If you increase

the load on the pump to the point that the engine can't generate enough

power to drive the pump, the engine will slow down. Since that slows

down the pump, it reduces the load on the pump and the system stabilizes

at the new, lower RPM. Likewise, if you reduce the load on the pump, the

RPM of the engine will increase until it reaches equilibrium between the

power output of the engine and the load on the pump. In most cases the

load on the pump is controlled by means of a valve on the output side of

the pump. Take a look at the diagram in Figure 1 and you'll get the

idea. By putting a valve in the line running out of the pump, you can

control how hard the pump has to work. As you close down the valve, the

pump tries harder to push the water or oil through the smaller opening.  The farther you close the valve, the harder it works. Just a note here

for you do-it-yourselfers, you need a "positive displacement"

type pump for this application. That is, it must be a pump that mechanically

forces the fluid through the pump. Typically, this is the type of

pump that uses two gears that mesh together and force the fluid out of

the pump outlet. A turbine type pump, like you might use to draw water

from a well or to circulate water through a heating system, just won't

work. If you close down the output side of a turbine pump, it simply

spins idly and won't apply the needed load to the engine. With the

proper type of pump, if you close the output valve completely, the pump

may barely turn at all. It will virtually lock up solid!

The farther you close the valve, the harder it works. Just a note here

for you do-it-yourselfers, you need a "positive displacement"

type pump for this application. That is, it must be a pump that mechanically

forces the fluid through the pump. Typically, this is the type of

pump that uses two gears that mesh together and force the fluid out of

the pump outlet. A turbine type pump, like you might use to draw water

from a well or to circulate water through a heating system, just won't

work. If you close down the output side of a turbine pump, it simply

spins idly and won't apply the needed load to the engine. With the

proper type of pump, if you close the output valve completely, the pump

may barely turn at all. It will virtually lock up solid!

As

I mentioned before, the fluid for this type of dyno can be either oil or

water. Water is more widely used, because it's cheaper, easy to

replenish, and generally easier to handle. In fact, you don't really

even have to recirculate it if you don't care to; just bring it into the

pump from whatever source, and send the output down the drain. While

that's pretty wasteful (and not too environmentally sound), it does

avoid any problems with controlling fluid temperature. You see, as you

force the fluid, be it water or oil, through the pump and then through

the restriction of the output valve, it heats up. The more energy it

absorbs from the pump, the more it gains heat.

This not only makes the whole apparatus hotter and more difficult to

work with, but it can change your output readings as well. If you're

going to use a fluid brake dyno for any serious work, you really will

need to develop a system to maintain consistent fluid temperatures.

Obviously, the larger a reservoir you use for the fluid, the easier it

will be to maintain an even temperature. But you'll probably need some

sort of cooling mechanism to circulate through, like a radiator core.

There are several reasons to consider oil as the fluid in the dyno,

rather than water. First of all, if you're looking at building something

yourself, positive-displacement oil pumps are generally easier to find

than positive-displacement water pumps. Worn-out hydraulic pumps have

found new life on small engine dynos for as long as I can remember.

They're relatively inexpensive, and the fact that they've worn to the

point that some of the oil slips past the impellers is a plus in this

application. That leakage inside the pump itself makes it a lot less

"touchy" on the control valve. Oil is also self lubricating in

the pump and does not create any rust or corrosion problems. On the down

side, an oil pump system must, of course, be recirculated, a

"closed loop"system. And, not only does the oil heat up even

more dramatically than water, but, as it heats up, it changes viscosity

dramatically. The hotter it gets, the thinner it gets. And as it gets

thinner, it flows through the valve more easily and your control with

the valve can get This not only makes the whole apparatus hotter and more difficult to

work with, but it can change your output readings as well. If you're

going to use a fluid brake dyno for any serious work, you really will

need to develop a system to maintain consistent fluid temperatures.

Obviously, the larger a reservoir you use for the fluid, the easier it

will be to maintain an even temperature. But you'll probably need some

sort of cooling mechanism to circulate through, like a radiator core.

There are several reasons to consider oil as the fluid in the dyno,

rather than water. First of all, if you're looking at building something

yourself, positive-displacement oil pumps are generally easier to find

than positive-displacement water pumps. Worn-out hydraulic pumps have

found new life on small engine dynos for as long as I can remember.

They're relatively inexpensive, and the fact that they've worn to the

point that some of the oil slips past the impellers is a plus in this

application. That leakage inside the pump itself makes it a lot less

"touchy" on the control valve. Oil is also self lubricating in

the pump and does not create any rust or corrosion problems. On the down

side, an oil pump system must, of course, be recirculated, a

"closed loop"system. And, not only does the oil heat up even

more dramatically than water, but, as it heats up, it changes viscosity

dramatically. The hotter it gets, the thinner it gets. And as it gets

thinner, it flows through the valve more easily and your control with

the valve can get  trickier. Temperature control with an oil-brake dyno

is critically important. If you expect to get any reasonable use out of

an oil-brake dyno, it must be fitted with an efficient, dependable oil

temperature control system. Better quality units include an oil

pre-heater to bring the fluid to a pre-determined temperature, as well

as a thermostatically controlled cooling system to keep it there. trickier. Temperature control with an oil-brake dyno

is critically important. If you expect to get any reasonable use out of

an oil-brake dyno, it must be fitted with an efficient, dependable oil

temperature control system. Better quality units include an oil

pre-heater to bring the fluid to a pre-determined temperature, as well

as a thermostatically controlled cooling system to keep it there.

You'll

recall that last month we talked about measuring the output of the dyno

by measuring the torque applied to the pump housing as the pump load

increased. The concept is pretty basic; the harder the engine tries to

turn the pump, resisted by the back-pressure created by closing down the

valve, the more the pump housing wants to twist. Measure that

twisting force and you're measuring torque. Conveniently, the torque on

the housing of the pump is always exactly equal to the torque on the input

shaft of the pump. But there is another alternative for measuring

engine output, if you're using an oil or water pump for the brake. By

accurately measuring the output pressure, between the pump and

the valve, you can gauge the torque on the pump shaft. But wait, it gets

even better. Most hydraulic pumps are factory rated with the torque to

output pressure figures. That means that you can directly convert the

readings on the pressure gauge into to foot/pounds of torque. And, since

this relationship is linear (i.e. if 10 ft/lbs = 50 PSI on a particular

pump, then 20 ft/lbs = 100 PSI), it makes it a snap to set up. All you

have to do is re-mark the face of the pressure gauge into foot/pounds

based on figures supplied by the pump manufacturer and you have a

direct-reading torque measuring dyno. See figure 2. For the home

builder, the pressure gauge readout is a heck of a lot easier to deal

with than trying to set up a spring scale or an electronic load cell.

There

are several good quality fluid pump type dynos commercially available,

as well as others that are not so good. Remember, the criteria for

selecting a dyno has to be; 1) can it give me the quality of data that I

need to make meaningful determinations about whatever tests I may be

running? and 2) will it hold up to the hard, repeated stresses that my

testing will subject it to? There

are several good quality fluid pump type dynos commercially available,

as well as others that are not so good. Remember, the criteria for

selecting a dyno has to be; 1) can it give me the quality of data that I

need to make meaningful determinations about whatever tests I may be

running? and 2) will it hold up to the hard, repeated stresses that my

testing will subject it to?

For

decades Stuska dynos have set the standard for small engine, fluid-brake

dynos. These units are robustly built to withstand continuous commercial

usage far beyond anything the average karter or engine builder is likely

to need. The Stuska unit utilizes a variation of the pressure gauge

system of data output, and load is controlled via a very finely threaded

valve on the output side of the pump. However, unlike systems that

directly read the output pressure of the pump, Stuska uses a

"torque arm" mounted to the pump housing. At the end of that

torque arm is a hydraulic cylinder, and the output of that cylinder is

measured by a pressure gauge. Stuska believes that this system gives

them the best combination of accuracy and repeatability.

They

are also readily adaptable to electronic readout and data collection by

simply substituting an electronic pressure transducer for the gauge.

These dynos are available in a variety of sizes and configurations from

big enough to test a motorcycle engine on to tiny enough to accurately

analyze the performance of a model airplane engine. There are probably

more Stuska dynos out there is use for karting applications than any

other manufacturer. In most cases, these units are mounted on custom

build test-beds designed to suit each users particular application, but

the manufacturer can provide ready-made platforms. They

are also readily adaptable to electronic readout and data collection by

simply substituting an electronic pressure transducer for the gauge.

These dynos are available in a variety of sizes and configurations from

big enough to test a motorcycle engine on to tiny enough to accurately

analyze the performance of a model airplane engine. There are probably

more Stuska dynos out there is use for karting applications than any

other manufacturer. In most cases, these units are mounted on custom

build test-beds designed to suit each users particular application, but

the manufacturer can provide ready-made platforms.

There

are other manufacturers out there marketing fluid-brake dynos

specifically designed for karting use. Some of these units feature

engine mounts and dyno stands already engineered to accept most modern

kart engines. Most maintain the proven principles of the Stuska-type

unit.

One

of these systems is available from Davenport Dynamometers, Inc. of

California. This unit features a sturdy platform that mounts both the

engine and the water brake. The load control valve, as well as sensing

and output hardware, are mounted on another framework, allowing these

control functions to be operated remotely, away from the howling engine.

While Davenport's unit is not remarkable from a mechanical standpoint,

their computer interface and data collection and analysis systems really

set this system apart. We'll talk more in another article about the

critical subject of gathering data from the dyno and making sense of it.

Another

fluid-brake system designed especially for karts is made by the

International Dyno Corp. and marketed by Franklin Motorsports of Oak

Creek, Wisconsin. Originally designed as a compact, all-in-one unit, at

under $1500 it put owning a dyno within almost everybody's reach. But

some serious users found the framework wasn't  stout enough to withstand

the rigors of daily use. Now International Dyno has a new model, more

robustly engineered. The new Model 500 Kart Dyno features a motor-mount

and hydraulic pump assembly that is separate from the rest of the unit.

The controls, including a oil temperature gauge, mount on the

water-cooled oil reservoir tank. The system is compact and, relatively,

portable. Like the Davenport Dyno, the Model 500 couples the engine to

the pump via a cog belt drive, like the ones enduro karts use. This

system provides smooth, clean power transmission with minimal friction

losses. The Model 500 utilizes "Pressure Gauge" output and is,

in it's standard form, only suitable for manual data recording. stout enough to withstand

the rigors of daily use. Now International Dyno has a new model, more

robustly engineered. The new Model 500 Kart Dyno features a motor-mount

and hydraulic pump assembly that is separate from the rest of the unit.

The controls, including a oil temperature gauge, mount on the

water-cooled oil reservoir tank. The system is compact and, relatively,

portable. Like the Davenport Dyno, the Model 500 couples the engine to

the pump via a cog belt drive, like the ones enduro karts use. This

system provides smooth, clean power transmission with minimal friction

losses. The Model 500 utilizes "Pressure Gauge" output and is,

in it's standard form, only suitable for manual data recording.

There

is one fluid-brake dyno on the market today that can be driven either

directly by the engine crankshaft, or by the axle shaft with the engine

still mounted to the kart. The DYNOmite Dynomometer system is

manufactured by Land & Sea of Salem, New Hampshire. These folks make

a variety of performance oriented products for marine applications, as

well as test equipment for snowmobiles, chainsaws, and so on. Unlike the

other fluid-brake dynos we've discussed, the DYNOmite unit uses

electronic torque measurement. You'll remember that earlier we talked

about measuring the torque output by measuring the twisting force on the

pump housing. Well, that's exactly what the Land & Sea folks are

doing. The DYNOmite unit has an integral "torque arm" built

right into the pump housing unit. And partway along the length of this

torque arm is an electronic strain gauge. A strain gauge is a device

that measures the amount of force that is trying to bend the surface

that it is mounted on. So, as the twisting force on the pump housing

increases, it puts more and more pressure on the torque arm and the

strain gauge measures that force. It is significant to note here that,

unlike that other commonly used fluid-brake dynos, the DYNOmite unit,

because of it's electronic output, and is automatically suited to

computerized data collection. That's not to say that the other dynos

can't be computerized. Quite the contrary. The Davenport Dyno is

specifically designed to support automatic data collection. But that's

not always the case. Most simple fluid-brake dynos are best suited to

manual data collection. That is, you stabilize the unit at a given RPM

setting, read the output information, write it down, and then adjust the

load to a new RPM setting and repeat the process. Manual data collection

is slow, and that extended run time makes it harder to "filter

out" variations in data that occur as engine temps and other

factors change. In general, the shorter the run time of your dyno runs

is the better quality your data will be. That makes electronic data

collection a high priority. In an upcoming article we'll get into the

advantages and pitfalls of electronic data gathering on the dyno. And

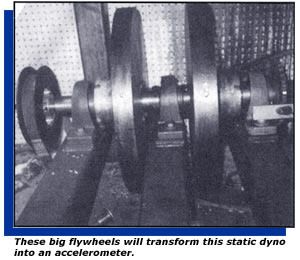

next month we'll look at totally electronic dynos; no water, no oil,

just lots of "juice" of another sort running the dyno,

providing the load, and measuring the output. Davenport Dyno is

specifically designed to support automatic data collection. But that's

not always the case. Most simple fluid-brake dynos are best suited to

manual data collection. That is, you stabilize the unit at a given RPM

setting, read the output information, write it down, and then adjust the

load to a new RPM setting and repeat the process. Manual data collection

is slow, and that extended run time makes it harder to "filter

out" variations in data that occur as engine temps and other

factors change. In general, the shorter the run time of your dyno runs

is the better quality your data will be. That makes electronic data

collection a high priority. In an upcoming article we'll get into the

advantages and pitfalls of electronic data gathering on the dyno. And

next month we'll look at totally electronic dynos; no water, no oil,

just lots of "juice" of another sort running the dyno,

providing the load, and measuring the output.

In

the meantime, start asking around about what sort of dyno facilities

your local engine builder might have available. If you're serious about

your karting, you can't afford not knowing what your engine is doing.

Being able to accurately predict where your engine will make peak torque

and where the output falls off to the point that you don't want to turn

any more RPM will work wonders with your on-track performance. Even more

important is knowing what to expect when you change pipes, or carbs, or

fuel mixtures. Oh, I know you can figure these things out by what

happens on the racetrack, and I know that there is no substitute for

track testing, but you can certainly make better use of the limited

track time you have if you've done your homework on the dyno before you

headed out. A good, accurate, repeatable dyno is an invaluable tool and

no top-flight engine builder should be without one. As karting gets more

and more professional and karters take their sport more seriously, more

individual karters are getting into dynos as well. This is one area

where knowledge really is power.

Karting

Dynomometers - Part 3

About

Us | Karts | Parts |

Schedules | Resources | Contact

|